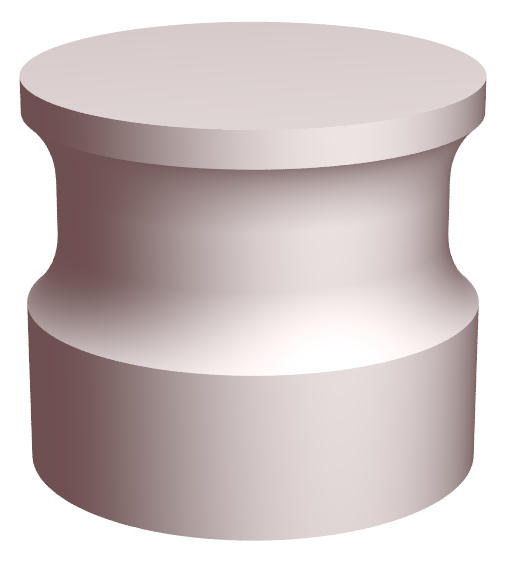

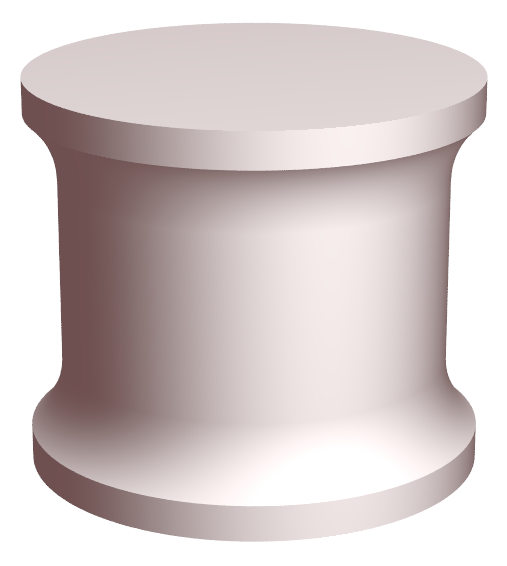

Spool_horn

Large diameter solid cylindrical horns have lower amplitude at the edge of the horn face than at the center of the horn face. This is caused by the Poisson coupling effect. (See details.)

To counteract this, the sides of the horn can be undercut (fluted) behind the face, thereby creating a flange at the front. This flange increases the amplitude at the edge of the horn face, thereby increasing the uniformity across the horn face. Such a horn design is called a spool horn because its shape looks somewhat like a spool of thread.

Because spool horns have no slots, they have much lower stress and much longer life than slotted cylindrical horns. Also, spool horns have very good face uniformity, generally better than 90% if the horn diameter is less than the thin-wire half-wavelength. (This excludes spool horn sizes which have detrimental interactions with asymmetric resonances (e.g., a Ø100 mm spool horn at 20 kHz)).

As the spool horn diameter increases, the radial face amplitude also increases. Thus, the maximum spool horn diameter is limited to about one thin-wire half-wavelength.

|

||||||||||

|

See design procedure for standard spool horns.

Also see —

Full spool horn

High-gain spool horn

Standard spool horn