Joints

Contents

- Figures

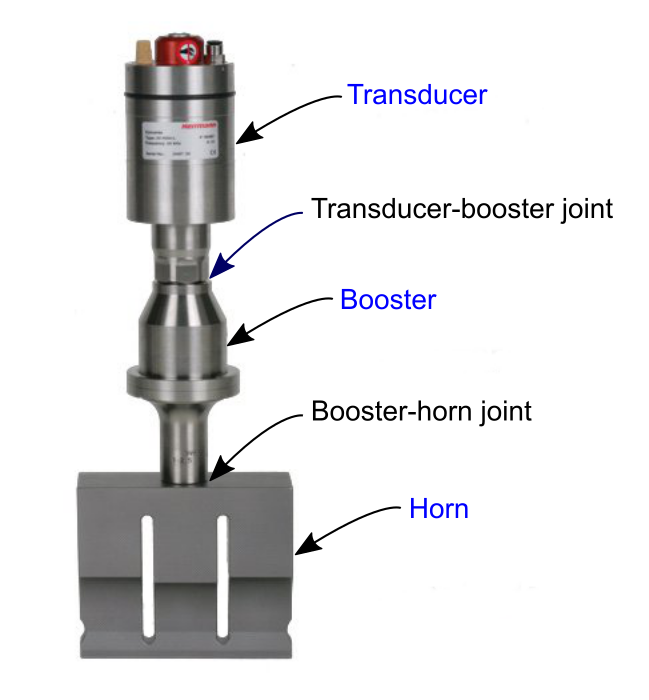

- Figure 0. Joints for industrial ultrasonic stack

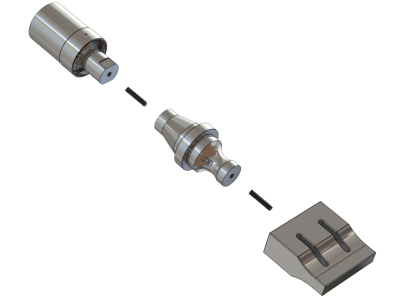

- Figure 0a. Industrial ultrasonic stack assembly

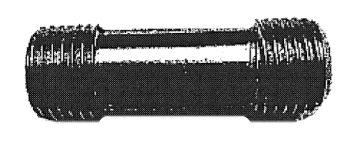

- Figure 0b. Necked stud

- Figure 1. Mylar washer

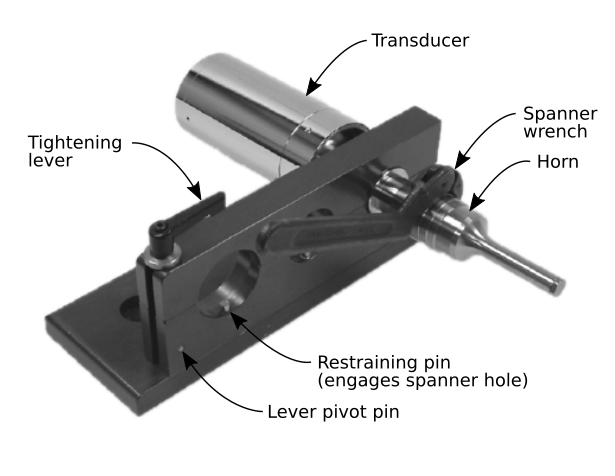

- Figure 2. Spanner wrenches

- Figure 3. Crowfoot (clawfoot) wrench adapter

- Figure 4. Clamshell tightening fixture (Branson Ultrasonics)

- Figure 5. Strap wrench

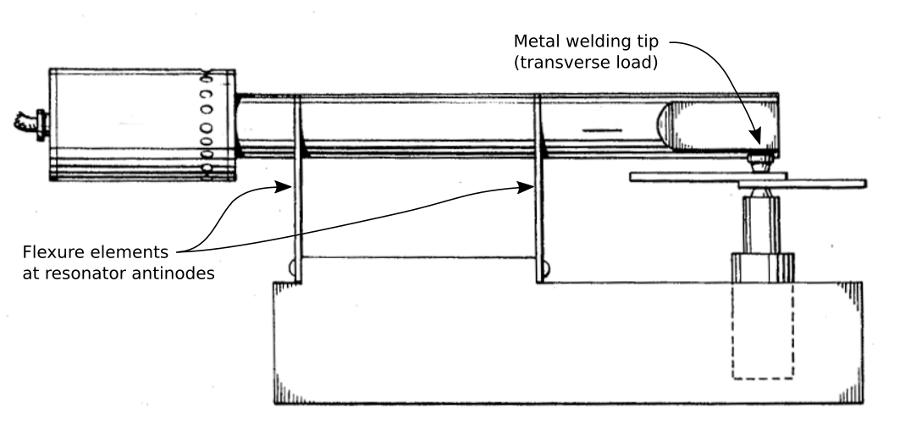

- Figure 6. Metal welding stack supported by flexure elements

- Figure 7. Effect of joint tightness on nonlinear response

A joint is an interface (area of contact) between adjacent components of an ultrasonic stack. The purpose of the joint is to efficiently transfer ultrasonic energy across the joint and to provide axial and lateral stiffness to the assembled stack. Typical joints include the transducer-booster joint and the booster-horn joint.

|

|

|

Joints are typically secured by threaded studs which permit easy assembly and disassembly. However, other means of securing (e.g., welding or adhesives) are sometimes used. Fretting at ultrasonic joints (especially those at high amplitude) is a common problem. Such fretting requires periodic joint maintenance.

|

|

|

Joint locations

For axial mode vibration, resonators are designed to vibrate in half-wave increments where each end is an antinode. Hence, the antinode ends are natural attachment points between adjacent resonators (e.g., between the horn and booster). The ultrasonic (inertial) forces at these antinode joints are low so relatively little static force should be needed to adequately secure these joints.

In some cases, however, joints are located away from antinodes (e.g., for tips). Joints for many of the components in a piezoelectric transducer are located away from the antinode.

Design

Machining specifications

The following table shows typical machining specifications.

|

|||||||||

|

Required joint amplitude uniformity

BUC - 1-slot 4.5" wide bar horn with ears.

Contact area

Contact between resonators usually occurs at the resonator's nominal dimensions. For example, suppose a booster's nominal output diameter is Ø40 mm in order to achieve the desired gain. Then it would normally be joined to the horn at the Ø40 mm diameter. However, this might not be optimal. In fact, there are several instances where a reduced contact diameter has shown improved performance. This reduced contact diameter is achieved by machining a short boss on either the output surface of the booster or the input surface of the horn. Since the boss height is small (e.g., 0.5 mm), the frequency and gain of the associated resonator are relatively unaffected.

Tip horns on composite horns

Joint deterioration (fretting)

Ultrasonic joints may deteriorate due to fretting. This causes frictional heating at the joint and fretting debris (which then leads to further deterioration). Eventually the joint may deteriorate to the extent that it causes squealing; such instability can damage the transducer. In extreme cases the joint may literally become fused so that it can't be disassembled. Fretting damage is cumulative; the longer fretting continues the worse the condition becomes. In particular, titanium has poor fretting resistance. (Youn[1])

Fretting will result if there is relative (frictional) motion between the two mating joint surfaces. Such relative motion can only occur if the mating joint surfaces are subjected to driving forces. If the joint is located at a longitudinal antinode then, in theory, no force should be present. However, this strictly applies only where the joint diameters are small and where the material on each side of the joint is the same. If these conditions are not true then there may be incompatibilities in amplitude uniformity or radial amplitudes at the joint. Such incompatibilities induce the forces that may lead to fretting.

(Note — The condition of zero force (stress) at an antinode is strictly true only when a horn is running in air (no power delivery). When power is delivered to a load, a traveling wave passes along the stack and through the joint. This traveling wave has associated stresses which may also contribute to fretting. It is not known if these stresses are sufficient to cause fretting.)

What about joints that are located away from an antinode (e.g., for tips)? Although these joints experience inertial forces, these forces are aligned with the resonator axis, rather than in-plane with the joint surface. Hence, such joints will not necessarily experience fretting.

The probability of fretting increases with the joint amplitude. For example, fretting is rarely a problem at the transducer-booster joint which has low amplitude (e.g., 10 microns peak at 20 kHz). However, fretting can be significant at the booster-horn joint when a 2.5:1 booster is used.

Titanium

In its natural state titanium is relatively inert. This is due to an oxide film that quickly forms over any raw titanium. However, raw titanium is very reactive in the absence of this oxide film. Thus, if the oxide film is abraided (e.g., by fretting) then the exposed titanium will tend to react with an adjoining metal. This is particularly true if the adjoining metal is also titanium (e.g., a titanium booster mated to a titanium horn). This titanium-titanium fretting is a particular problem for orthopaedic joint replacements and has been studied extensively.

Different diameters

Effect of stud

A stud distorts the amplitude across a joint. The distortion depends on the modulus of the stud relative to the resonator. For example, consider a joint between two Ø40 mm resontors, one made of Ti-6Al-4V and one of Al 7075-T6. The following table shows the relative axial amplitude uniformities of these resonators.

Surface finish

Surface finish may significantly affect fretting. In tangential loading of a bolted stainless steel interface at 25 Hz for 1.08 million cycles, Li found that increasing the average surface finish (Ra) from 1 μm to 4 μm ---

Joint clamp force distribution

In a typical resonator the thread that accommodates the stud starts close to the interface surface (except typically for a countersink at the thread's entrance). Then when two such resonators are tightened together the clamp force of the stud on the joint is concentrated a the joint nearest to the stud. Moving radially on the joint away from the stud, the clamp force decreases, declining to a minimum at the edge of the joint. This nonuniform clamp force distribution can lead to fretting, especially toward the joint periphery where the clamp force is low.

Stegelmann[1] patent 6841921B2 claims that the clamp force distribution can be improved and fretting can be reduced by a design whereby the stud only engages the resonator's threads away from the joint. This is accomplished either by removing a central portion of the stud threads (necking the stud) or by counterboring the resonator's threads so that these threads are removed to the desired depth. Then the force of the stud is exerted from deeper within the resonator rather than near the joint so that the force on the joint is more evenly distributed across the joint.

|

|

|

While the theory behind Stegelmann's patent is valid, the novelty (for patent purposes) seems doubtful. For example, this method has been used to improve the static pressure distribution across the piezoelectric ceramics in a transducer. (See details.) In any case, counterboring of tapped holes is not uncommon so restricting this practice (by patent) at an ultrasonic joint would seem unreasonable. (Stegelmann's patent expires in November 2022.)

To improve the force distribution across the joint, Culp[0] machined a shallow recess in the resonator's face, leaving only a contact ring near the periphery of the resonator's face. For example, for a resonator (e.g., booster) with a Ø40 mm face diameter, a Ø30 mm x 0.5 mm deep recess was machined into the face, thereby leaving a 5 mm wide contact ring around the periphery. Because this contact ring is relatively narrow, the force distribution across the ring is relatively uniform. This method is particularly useful for joints that are subject to transverse loads, such as in ultrasonic metal welding.

Delivered power

Protection

Various interface materials have been tried in order to extend joint life.

Shims

Thin disposable shim washers have been used. Shim materials include copper and brass, typically less than 0.2 mm thick. A number of ultrasonic companies now recommend mylar washers. Mylar washers are normally used without lubricants.

Dukane[1] (p. 18) cites the following benefits of mylar washers compared to silicone grease —

- In most cases the washer will last longer in production.

- Interface fretting (deterioration) is reduced.

- Stack assembly is more consistent since the washers have consistent thickness.

- Stack disassembly will often require less torque and reduce the possibility of damaging components.

However, Dukane[1] (p. 13) also notes that mylar washers will creep under pressure so a maintenance plan should include periodic inspection and replacement.

|

|

|

Lubricants

Several companies recommend mylar washers as a first choice. However, they may recommend silicone grease as a (generally less effective) alternative.

- Dukane[1] (p. 13) recommends a thin layer of Dow-Corning #4 high temperature, high pressure silicone grease (or #111 as an alternative).

- Branson[4] (p. 2) recommends Dow-Corning #111 for 40 kHz stacks — "Typically, 40 kHz does not generate enough amplitude to create fretting corrosion." However, for 15 kHz to 30 kHz stacks Branson says that using mylar washers (instead of silicone grease) will minimize fretting corrosion.

High pressure anti-seize greases have been used effectively. Of these, molybdenum based greases (such as Dow Corning's Molykote M-77 (dowcorning.com), suitable up to 400°C) are popular. Others may be equally effective.

One company uses a thin layer of transparent Teflon spray. The results are reportedly good. Culp[0]

However, for their 20 kHz seam welder with decoupling disks (probably titanium), Stapla Ultrasonics[1] recommends, "The coupling surfaces must be free of grease and oil." (p. 14)

Notes —

- Many lubricants may not be suitable where biocompatibility is required.

- At one time stopcock grease was widely used. However, stopcock grease is designed to seal against vacuum leaks in laboratory chemical equipment. Its lubricating properties are poor and it leaves a hard residue after longterm use.

Platings

Chrome, anodize

Other

If the above suggestions are not adequate then the following can be tried.

- Increase the horn gain. For the same output amplitude, this will reduce the amplitude at the booster-horn joint.

- Eliminate the joint. Make the horn and booster from a single piece of material (i.e., a full-wave horn), thereby eliminating the troublesome joint. This may be somewhat unrealistic if the horn is rectangular, especially if the horn is large so that significant raw stock removal would be required in order to achieve the booster shape.

- Fuse the joint. The joint can be fused by electron beam or laser beam welding. These might require a raised pad on the horn in order to allow the beam to access to the joint. Spin welding and brazing might be possible, depending on the horn and booster materials. However, spin welding is typically reserved for high volume applications. The fused joint might be formed by hot isostatic pressing (HIP) — e.g., see Ehlert[1] patent 8,459,122 B2.

Tightening

Tools

In order to tighten two resonators together, the mating resonators must be machined to accept the appropriate wrenches. The wrenching geometry is typically either wrench flats (to accept open-end wrenches) or radial holes (to accept spaner wrenches). Spanner wrenches are common but have the following limitations —

- They can strip out the resonator's spanner holes with continual use, particularly with aluminum resonators.

- They are only suitable for cylindrical resonators.

- They are not available for small diameter resonators.

- The torque that can be applied is limited, either because the spanner's pin will break or the pin will slip from the spanner hole.

- If they are to be used with a torque wrench then they need a special, uncommon adapter (figure 2b). (In contrast, wrench flats only require a crowfoot wrench adapter (also called a clawfoot wrench adapter) which is much more widely available.)

Spanner wrenches can be advantageous where there is limited room for a conventional wrench or when a conventional wrench would be unacceptably large.

|

||||||||||

|

|

|

|

Figure 4 shows a common type of clamshell fixture for resonators with radial spanner holes. In this illustration the fixture engages the spanner holes of the transducer while a spanner wrench engages the spanner holes of the horn. (Note in this case that the spanner wrench is engaged so as to loosen the horn.) This particular fixture has two additional holes to accommodate resonators of different diameters. Simple variations of this design are possible (e.g., by substituting a bench vise with appropriate jaw adaptors for the clamshell).

|

|

|

If a resonator does not have a means for applying a wrench (e.g., a bar horn, block horn, or large cylindrical horn) then a fabric or rubber strap wrench may be used. Alternately, it may be clamped in a vise with soft jaws (e.g., aluminum or copper) so that the resonator's surface will not be marred. Otherwise, such marring could be a location for fatigue crack initiation.

|

|

|

Caution

When tightening a joint, the booster should not be held by its mounting rings and the transducer should not be held by its housing. These typically have anti-rotation pins that are not designed to withstand high torque.

Torques

A certain static joint force is needed to maintain intimate contact between mating joint surfaces. Since the applied static force can't be easily measured, joint torque is used as a proxy. However, the force exerted by a given torque will depend on factors such coefficients of friction for the joint and threads (depending on lubricants, finishes, materials), machining (joint finish, perpendicularities), thread pitch, contact area, etc. (See Nutek[1], p. B–4) For example, the following will give different joint forces for identical torques —

- Different coefficients of friction

- Unlubricated versus lubricated

- Mated resonator materials — titanium-titanium, titanium-aluminum, aluminum-aluminum

- Interface shims — copper versus mylar

- Stud material — steel versus titanium

- Different thread pitches — 3/8-24 thread versus 1/2-20 thread

- Different contact diameters — 25 mm versus 40 mm

For joints with nominal parameters (assuming well designed), Nutek[1] (p. B–43) indicates that a specified torque will produce a joint force that is only accurate within ±35%. Unbrako (p. 62) estimates this as ±25%.

Thus, the joint force from a given torque is very approximate. Hence, comparisons among torque recommendations are difficult to evaluate.

Horns without substantial transverse loads

In most ultrasonic applications there is either no static load applied to the horn's output face (e.g., liquid processing) or the static load is mainly parallel to the stack axis (e.g., plastic welding). Then the joints are loaded mainlly in compression. (Note — If a plastic welding horn is wide and if contact is not uniform across its face then the joints will also experience some static bending moments which must be resisted.)

|

|||||||||||||||||||||||||||

|

Table notes —

- References —

- Branson Ultrasonics[3] (p. 2)

- Dukane[1] (p. 14)

- Patsonics[1]

- Sonics & Materials[2] (p. 12) — cautions not to overtighten

Table 1 shows that Dukane recommends significantly higher tightening torques than Branson. Dukane notes that, "Horn and booster torque specifications are higher than stud torque specs. Be sure to tighten the horn or booster joints to the higher torque limits." (p. 14) On the other hand, Branson's joint torques are generally less than its stud torques, ostensibly to keep the bottomed stud from loosening from the bottom of the stud hole as the joint is tightened. (Culp[0]) However, the joint torque of Branson's metal welder (108 Nm, below) is 2x greater than its 51 Nm recommended torque for the ½‑20 stud; none-the-less, these joints are relatively trouble free. Also, in one case a Branson customer tightened the horn to a titanium booster at approximately 3x Branson's recommended torque and reported good results. (Culp[0]) However, this customer may also have changed joint lubricants at the same time. Thus, the wide variation in joint torques shows that the effects of joint torque on performance and joint longevity are not well understood.

Cardoni[1] (p. 179) notes, "It has always been understood in the high power ultrasonics community that careful assembly of system components is critical for good system performance. There have been many "rules of thumb" applied, concerning stud sizes, stud position and torque requirements for joining components, although there are inconsistencies between manufacturers recommendations."

Horns with substantial transverse loads

In shear welding applications (metal welding, tube sealing) the horn's output surface is on the side of the horn rather than on the face (figure 6). When the static (transverse) load is applied to this output surface, the joints experience bending moments that tend to cause the joints to open. Hence, the joints must be tightened tighter than normal.

|

|

|

|

||||||||||||||||||||||||

|

Table notes —

- The torque value is for both the transducer-booster and booster-horn joints. (Stapla Ultrasonics[2], pp. 12, 49)

- The seam welder uses decoupling disks. (Stapla Ultrasonics[1], p. 14) "The coupling surfaces must be free of grease and oil." The lack of lubrication means that the resulting axial force at the joint will be less than othewise expected.

- Polar mount (Culp[0])

Nonlinear behavior

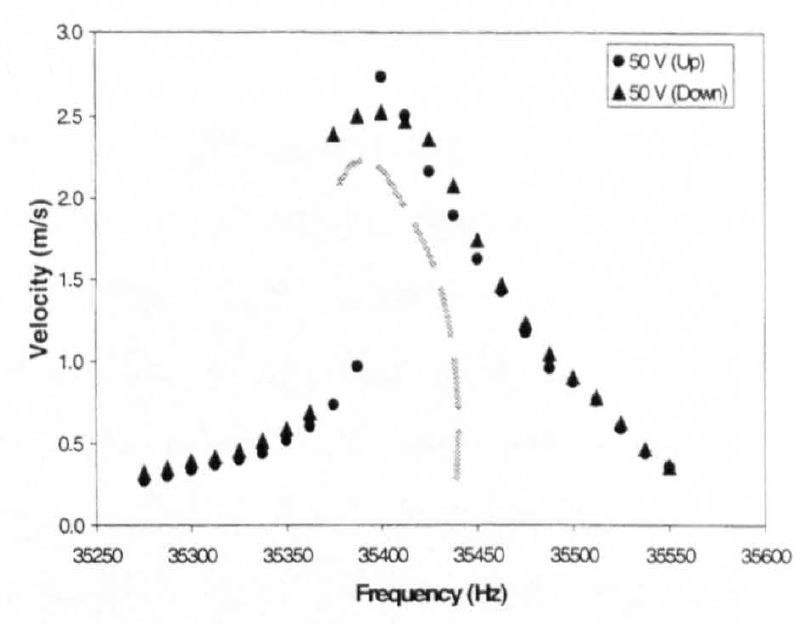

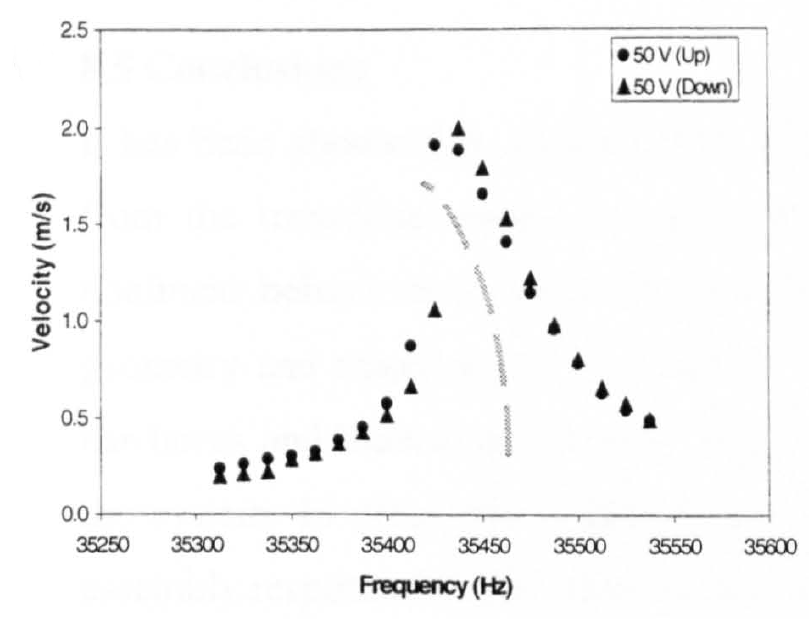

Figure 7 shows data from Cardoni[1] who indicates that a "tighter" joint reduces nonlinear behavior. However, no details of the test are given so generalization of this conclusion is difficult. (For an ideal joint, the broken lines of figures 7a and 7b would be completely vertical and a curve fitted to the data points would be symmetric left-to-right about each line.)

|

||||||||||

|

Mathieson[1] (pp. 146-151) provides some additional information. However, Mathieson does not provide specific torque values but only classifies his joints as "loose" and "tight". Presumably there is a limiting torque (joint stress) beyond which the ultrasonic performance doesn't substantially improve further. (This would be similar to the piezoceramic prestress data of Hulst, figure 5b.) However, this limit can't be determined from Mathieson's limited data.

Based, in part, on related studies, Mathieson[1] (p. 151) concludes, "The join between two component of a tuned ultrasonic assembly can have a large effect on the performance and whether strong nonlinear behaviours are exhibited by the device. Important factors in achieving a stable and reliable ultrasonic joint are high accuracy between the bearing surfaces combined with as high a torque as allowable between the two joining parts."

Tips

See here for standard tips.

Joining

EB welding, brazing

Maintenance

Joints may deteriorate over time. The exact deterioration rate for a particular stack configuration can't be easily estimated; it must be established through experience. Dukane[1] (p. 15) recommends inspecting the stack joints after the first 200-400 hours of operation. If the joints are acceptable then double the inspection interval. However, if the joints require reconditioning then halve the inspection interval.

Reconditioning

If an interface surface has deteriorated then it can often be reconditioned by removing a small amount of material.

Manual reconditioning

If the deterioration is slight then the surface can be reconditioned by hand. The following process is recommended (with slight variations) by Branson (p. 3), Dukane (p. 25), Patsonics[1], and Sonics and Materials[2] (p. 20).

- Removed the stud (as needed) and wipe the surface clean.

- Tape a clean sheet of #400 grit (or finer) emery cloth grit side up to a clean, flat surface such as a piece of plate glass.

- Hold the resonator between the thumb and index or middle finger near the bottom of the resonator. This position will reduce the tendency of the resonator to rock (which would produce a convex surface) or shudder.

- While applying minimal downward force, push or pull the resonator gently across the emery cloth in one direction. (Note — Sonics & Materials recommends a figure 8 pattern. However, Patsonics specifically states that the resonator should be pulled in a straight line, "not in a figure 8 or other pattern.") Repeat once.

- Rotate the resonator 120° and repeat step 4. Repeat.

- Repeat steps 4 and 5 until all pitting and contamination have been removed.

- Place a straight edge, such as the edge of a metal ruler, across the repaired surface and hold this up to the light. If any light can be seen at the periphery of the repaired surface then the surface is convex. This surface can only be repaired by machining.

- Install a stud to specification. (If the original stud was unbottomed then it can be re-used. However, if a threadlocking material had been applied then that material should first be removed. This can be done by running the stud lightly through a die or by using a wire brush. If the original stud had been bottomed then it should be replaced since the point would likely have been damaged from the first installation.)