Titanium Properties

Contents

- Uses

- Cross references

- Properties

- Ti-6Al-4V

- Ti-6Al-4V — annealed

- Ti-6Al-4V — other conditions

- Ti-7Al-4Mo

- Fabrication

- Recommendations

- Appendix A - Young's Modulus for Ø38.1 mm Ti-6Al-4V Rod

- Appendix B - Young's Modulus for Ti-6Al-4V Plate

- Appendix C - Titanium with Low Young's Modulus

- Appendix D - Titanium for Biomedical Use

- Appendix E - Other Titanium

- Figures

- Figure 1. Grain direction in Ti-6Al-4V

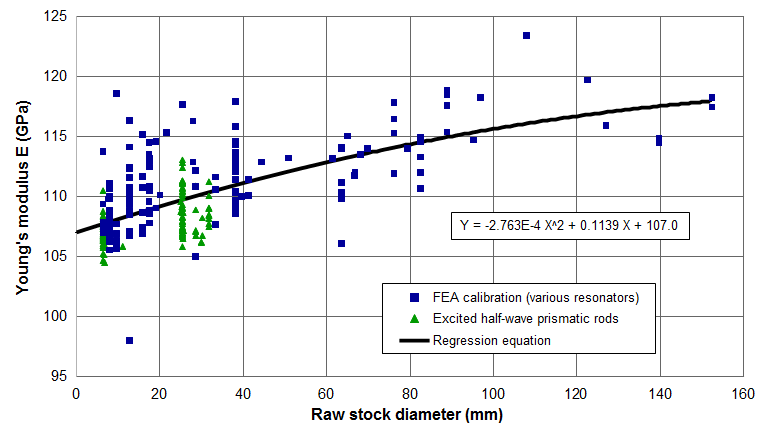

- Figure 2. Ti-6Al-4V — Effect of raw stock diameter on Young's modulus

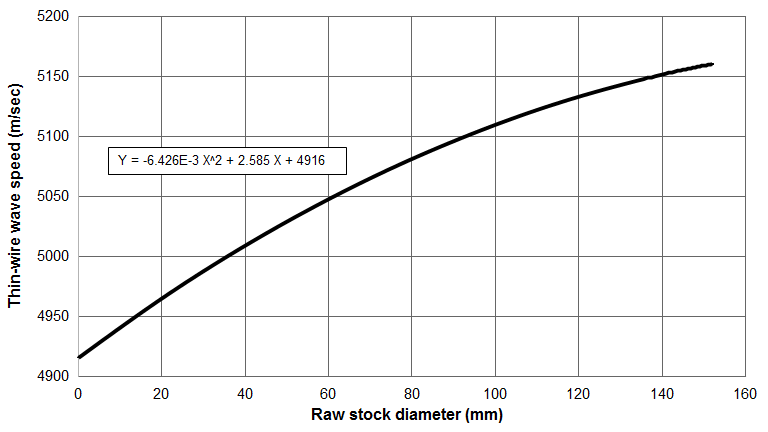

- Figure 3. Ti-6Al-4V — Effect of raw stock diameter on thin-wire wave speed

- Figure 4a. Variation of Young's modulus for Ø7.9 mm Ti-6Al-4V rod

- Figure 4b. Variation of Young's modulus for Ø12.7 mm Ti-6Al-4V rod

- Figure 4c. Variation of Young's modulus for Ø38.1 mm Ti-6Al-4V rod

- Figure 5. Effect of temperature on Young's modulus for Ti-6Al-4V sheet

- Figure 6. Internal friction (Q-1) in annealed Ti-6Al-4V at 17.6 kHz

- Figure 7. Internal friction (Q-1) in unannealed Ti-6Al-4V as a function of frequency

- Figure 8. Ultrasonic test setup to measure material loss

- Figure 9. Ultrasonic power loss of acoustic materials at 15 kHz

- Figure 10. Effect of test direction on fatigue for 57 mm thick Ti-6Al-4V forged and annealed bar (rotating-cantilevered test)

- Figure 11. Effect of processing on fatigue of Ti-6Al-4V

- Figure 12. S-N fatigue curves for Ti-6Al-4V annealed and STA (rotating beam test)

- Figure 13. Branson Ultrasonics metal welding horn

- Figure 14. Machinability of Ti-6Al-4V relative to various tool steels

- Figure 15. Spiral tap (from OSG USA)

- Figure C1. Stress–strain curves of solution treated (ST) and cold rolled (CR) specimens — (a) Ti‑5Nb‑9Zr, (b) Ti‑10Nb‑9Zr, (c) Ti‑15Nb‑9Zr

- Tables

- Table 1. Orthotropic properties of Ti-6Al-4V

- Table 2. Ti-6Al-4V — chemical composition

- Table 3. Variation of Young's modulus for Ti-6Al-4V rod

- Table 4. Variation in Young's modulus along a titanium bar

- Table 5. Q measurements for Ti-6Al-4V

- Table 6. Properties of Ti-6Al-4V (various conditions)

- Table 7. Properties of Ti-7Al-4Mo (annealed and STA)

- Table 8. Proposed benefits of Ti-7Al-4Mo compared to Ti-6Al-4V

- Table 9. Fatigue properties of Ti-6Al-4V (various conditions)

- Table A1. Measured values of Young's modulus for Ø38.1 mm Ti-6Al-4V rod

- Table B1. Calculated values of Young's modulus for Ti-6Al-4V plate (longitudinal grain direction)

Uses

Titanium alloys are used for their combination of good acoustic properties.

- Long life for highly stressed resonators.

- Biological compatibility for surgical instruments or implants.

- Moderate resistance to impact, wear, and cavitation erosion.

- Chemical resistance.

However, titanium is relatively expensive so other materials should be used where appropriate.

Applications include medical (surgical), plastic and metal welding, liquid processing, and food packaging and cutting.

Cross references

A specification cross reference for various grades of titanium can be found here. This cross reference includes U.S., British, French, and German designations.

Nomenclature

Titanium alloys are named for their principal alloying elements (percentage by weight, nominal); however, additional minor elements may also be present. For example, Ti-6Al-4V designates an alloy that nominally contains 6% aluminum and 4% vanadium.

Important — By itself, the chemical composition is not sufficient to determine the performance of a titanium alloy. (This would be like trying to evaluate a wine by just knowing the grapes from which it was made.) Instead, the entire thermomechanical production process (which controls microstructure) must be specified.

Properties

Orthotropic considerations

Titanium is orthotropic which means that the material properties depend on the direction in which the material is tested with respect to the grain direction. The grain directions are commonly labeled as longitudinal L (i.e., parallel to the grain), transverse T (also called long transverse LT), and short transverse ST. See the following figure from Bowen[1] (p. 1273).

|

|

|

Bowen (p. 1272) lists the following properties for this material. Note the substantial dependence on the test direction.

|

||||||||||||||||||||||||

|

Table notes:

- The material is Ti-6Al-4V, forged and annealed, 235 mm wide x 57 mm thick .

- E = Young's modulus.

- The thin-wire wave speed \( c_{tw} \) is calculated as \( \sqrt{E/\rho} \) where the assumed density \( \rho \) is 4430 kg/m3. These \( c_{tw} \) values were not included in Bowen's original table.

- The fatigue strength is approximate at 107 cycles.

For titanium Young's modulus and the wave speed depends on the following factors:

- The direction of vibration with respect to the grain direction (see the table).

- The position of the raw material along the length of a bar.

- The heat from which the sample was produced. Variations may also occur from different samples of the same heat (see below).

- The raw stock type (rod, bar, sheet, or plate).

- For rod material, the raw stock diameter (see below).

Thus, because the wave speed or modulus of titanium may not be precisely known, the tuned length of a titanium resonator will not be entirely repeatable and may not be precisely predicted, even using computer simulation.

Cross rolling

Titanium's directionality can be reduced by cross rolling. In this process the plate material is successively rolled in transverse directions as its thickness is reduced. Arthington[1] (p. 6) reports that TIMET uses this process for critical reliability aero-engine compressor blades manufactured by Rolls Royce plc.

Loss (Q)

See here for Ti-6Al-4V data.

Variation with grain direction

Limited experimental data suggest that the loss depends on the vibration direction relative to the grain.

Fatigue characteristics

Titanium alloys have an endurance limit (stress) below which the material will have infinite life. However, the exact value of this endurance limit is somewhat difficult to determine. See the discussion below for Ti-6Al-4V.

Wear

Abrasion

Titanium's resistance to abrasion is substantially better than aluminum but not as good as hardened steel. Several methods are available for improving the wear resistance.

Inserts

Titanium-carbide (TiC) inserts can be brazed to titanium flat faced horns.

- For high amplitude bar horns, experience has shown that the insert thickness should be less than ~1.8 mm in order to limit the inertial forces which could cause the insert to detach from the horn. Also, since carbide is relatively brittle the width of each insert should be limited to about 25 mm so that the carbide doesn't crack due to nonuniform amplitude on the horn's face. Of course, these suggested dimensions may be adjusted depending on the horn's amplitude and uniformity.

- Special care must be taken during brazing to insure a strong horn-carbide joint.

- The density of tungsten carbide (15600 kg/m³) is about three times greater than titanium carbide (4930 kg/m³). Use of tungsten carbide would then result in 3x greater stress on the horn-carbide joint. Hence, titanium carbide is generally preferred over tungsten carbide.

Coatings

Unlike inserts, coatings can be applied to non-flat surfaces. Also the application process may be easier. However, because these coatings generally have somewhat limited thicknesses they don't necessarily provide good impact resistance due to the relatively softer titanium base material. In addition, many coatings should not be applied to highly stressed regions because this may reduce the horn's fatigue life. Thus, masking of the horn may be needed.

D‑Gun

D‑Gun is a proprietary process developed by Union Carbide and now offered under Praxair[1]. A number of coatings are available, typically with thicknesses up to about 1 mm in ultrasonic applications.

For one automotive customer who was ultrasonically staking a glass-filled resin, a D‑Gun coating of 0.025 mm - 0.050 mm resulted in eight times the normal wear life. At the end of the wear life the remaining D‑gun was stripped and the horn was recoated.

LW‑1N30 (principally tungsten carbide, Rc 70) has been used successfully when applied to aluminum 40 kHz loom slitter horns (to slit and simultaneously seal cloth edges as the cloth is woven in a loom).

Diffusion surface hardening

"Diffusion hardening is performed by completely surrounding a metal part with the element to be diffused into it in either the solid, liquid, or gas phase depending on the type of diffusion process being performed. The concentration of the diffusing element surrounding the part must be higher than the concentration of the element inside the part, or diffusion will not occur. The metal and the surrounding element must then be heated to a temperature sufficiently high for diffusion to occur." (https://en.wikipedia.org/wiki/Diffusion_hardening)

The concentration of diffused interstitial atoms is mainly confined close to the surface of the titanium base material and decreases rapidly with depth. Hence, the hardness shows a similar pattern. The effective hardness depth may be on the order to 50 micro-meters (see Güleryüz[1]).

The hardness of Ti-6Al-4V is typically taken as 35 HRC (Rockwell C) which is approximately 350 on the Vickers scale. Güleryüz[1] shows that diffusion hardening with oxygen, nitrogen, and boron produced surface hardnesses (Vickers) of 1200, 2000, and 2700 respectively. The particular results will depend on the process conditions, including temperature and exposure time.

The effect of diffusion hardening on fatigue should be evaluated. For biomedical applications the possibility of spalling should be investigated. Friction may be reduced.

Cavitation erosion

See cavitation erosion, particularly materials.

Ti-6Al-4V

When a titanium alloy is required, Ti-6Al-4V (6% aluminum, 4% vanadium) is most commonly used, in part because it is widely available. (As of 2000, Donachie[1] (p. 15) reports a 50% market share.) Because this alloy is widely used for non-ultrasonic applications (particularly aerospace), a huge knowledge base has been compiled. Ti-6Al-4V is approved in the U.S. and other countries for ultrasonic surgical devices.

Notes —

- Much of the discussion in this section is specific to annealed Ti-6Al-4V. However, some information (e.g., density) is common to all variations of Ti-6Al-4V.

- Ti-6Al-4V only designates the chemical composition. Some properties (and, hence, performance) may vary considerably depending on factors such as grain direction, heat treatment, processing, etc.

Chemical composition

The following table shows the allowed elements and concentrations for Ti-6Al-4V (TIMET[1], p. 1) —

Density

The usual density of Ti-6Al-4V is 4430 kg/m³.

Ti-6Al-4V — annealed

Variation of modulus and wave speed

Cylindrical stock

For annealed cylindrical stock, various tests by Culp[0] and an associate indicate that Young's modulus depends on the material's raw stock diameter (i.e., the diameter of the raw material from which the resonator was machined).

|

|

|

Each data point of figure 2 was generated by either of two methods.

- FEA calibration. The frequency of each resonator was measured. This measured frequency was compared to the FEA frequency which was determined with an assumed Young's modulus. The assumed Young's modulus was then adjusted until the FEA frequency agreed with the measured frequency. (For the frequency measurement the resonator was rigidly attached to a transducer whose nominal frequency was the same as the resonator. Then the transducer could have had some effect on the measured frequency.)

- Excited half-wave prismatic rod. A half-wave prismatic rod (length \( \Gamma \)) was lightly positioned above a transducer. The amplitude at the free end of the rod was measured with a non-contact instrument. The transducer's driving frequency \( f \) was adjusted until the rod experienced maximum axial amplitude (i.e., corresponding to the rod's fundamental axial resonance). Then, the thin-wire wave speed \( c_{tw} \) was calculated as —

\begin{align} \label{eq:15101a} c_{tw} = (2 \Gamma) f \end{align}

from which Young's modulus was calculated as —\begin{align} \label{eq:15102a} E = c_{tw}^2 \, \rho \end{align}

For both methods, the materials came from numerous melts and suppliers. No pattern could be determined among these.

The confidence in these results is high. Hence, the data scatter is most likely due to actual variations in the titanium material rather than measurement error. This is a known problem with titanium. (See the further discussion below.)

Using the regression equation for Young's modulus from figure 2, the thin-wire wave (\( \sqrt{E/\rho} \)) speed can be calculated (figure 3).

|

|

|

Data scatter

For the data of figure 2 there are three diameters that had a significant number of samples: 7.9 mm, 12.7 mm, and 38.1 mm. The following three graphs show the scatter for these diameters and the associated probabilities. For example, for the 38.1 mm diameter (figure 4c), 95% of the Young's moduli fall within a 9.6 GPa band with a mean of 111.8 GPa. (The raw data for the 38.1 mm diameter are given in Appendix A.)

|

|

|

|

|

|

|

|

|

The following table summarizes the above graphical information. Note that the 95% probabilities were calculated by assuming a normal distribution of the data. This assumption is somewhat incorrect as indicated, in part, by the fact that the mean and median values for a given material diameter are somewhat different.

|

||||||||||||||||||||||||||||

|

Unfortunately, the data scatter shown in the above figures is not unusual for titanium. Figure 5 shows similar scatter for eight heats of Ti-6Al-4V sheet in both the longitudinal and transverse material directions (TIMET data[1], p. 14). At room temperature the data scatter for both material directions is approximately ±2.8 GPa. (From an orthotropic perspective, at room temperature the average Young's modulus in the transverse direction (~118 GPa) is about 5% higher than in the longitudinal direction (~107 GPa).)

|

|

|

In the above figure, WQ = water quenched; AC = air cooled.

Data from Culp[0] for an undisclosed titanium alloy (forged) show that Young's modulus can even vary along the length of a single bar. In these tests, the drive and pickup were both electrostatic so there was no attached transducer to contaminate the results.

|

||||||||||||||||||||||||||||||||||||

|

Repeated tests show that the data are very repeatable. Thus, the variation in Young's modulus along the bar must be due to actual variations in the material properties rather than testing errors.

Interestingly, Young's modulus for this material is higher in the longitudinal direction than in the long transverse direction. However, this conflicts with other known data for this material.

Plate stock

Since titanium is orthotropic, different moduli may be expected in each of the three material directions (longitudinal, transverse, short transverse). Although this information undoubtedly exists (aircraft manufacturers), it does not seem to be publically available.

Culp[0] has compiled data for horns whose longitudinal material direction is parallel to the principal direction of vibration (the stud axis). The procedure and data are given in Appendix B. Excluding the one outlier at 132.4 GPa, the average modulus is 119.6 GPa. Except for the one outlier the data scatter is reasonable and does not appear to depend on the horn's thickness.

Poisson's ratio

A wide range of values have been reported for Poisson's ratio. These values are affected by the same factors as the wave speed and modulus (above).

- "It is difficult to give a reliable value for Poisson's ratio for titanium alloys since anisotropy leads to small differences in both elastic and shear moduli which, when taken together to calculate Poisson's ratio, can lead to values varying from 0.287 to 0.391 for annealed ASTM Grade 5 (Ti-6%Al-4%V) sheet. However, the generally accepted value for commercially pure titanium is 0.36 and that for ASTM Grade 5 is 0.31." (AZO Materials)

- "Poisson's ratio depends on material texture and measurement directions. Ten observations at TIMET, using a two element rosette strain gage, gave a mean value of 0.342 with a range of observations from 0.287 to 0.391." (TIMET[1], p. 15)

- Barile[1] used a value of 0.32 for Ti-6Al-4V which he reported as "… an isotropic and homogeneous titanium alloy" (p. 161). It is unclear if this value was experimentally determined.

- Hampton[1] (p. 33) used a value of 0.334 when analyzing a 30 kHz transducer with a Ø45 mm Ti-6Al-4V front driver. The source of this value is not known.

- For 1 mm thick Ti-6Al-4V sheet material, Lecompte[1] reported an experimental value of 0.385 and a back-calculated FEA value of 0.36 ± 0.02.

- Wuchinich[5] measured flexural and torsional frequencies of a Ø63.6 mm cylinder and a Ø82.5 mm cylinder, both of Ti-6Al-4V. He then calibrated FEA model properties to give the same FEA frequencies as the measured frequencies. The calibrated value of Poisson's ratio was 0.288 for both cylinders. (The calibrated Young's modulus for the two cylinders was 114 GPa and 112 GPa, respectively. These values fall within the data scatter of figure 2.)

- McCulloch[1] (p. 524) used a value of 0.31 when analyzing a 35 kHz cutting blade. The source of this value is not known. (The grade of titanium was not specified but is assumed to be Ti-6Al-4V.)

- Derks[1] (p. 11) gives a value of 0.305 for a "Ti-alloy". The source of this value is not known. (The alloy was not specified but is assumed to be Ti-6Al-4V.)

- Culp[0] has found that Poisson's ratios between 0.32 and 0.34 give reasonable results for FEA.

- matweb.com specifies 0.342.

Loss (Q)

As indicated by the following table, Ti-6Al-4V has the lowest loss (highest Q) in the annealed condition. (The raw stock for all of these tests is believed to be cylindrical.)

|

||||||||||||||||||||||||||||||

|

Notes —

- The Wuchinich[2] material was heated to 940 °C (1725 °F) for one hour and then water quenched, giving a Rockwell C hardness HRC of 65 (p. 4).

- The Mason[1] material from figure 6 below was annealed in a vacuum at 760 °C (1400 °F) for one hour (p. 1927).

- The Mason[1] material from figure 7 below was "unannealed" which seems to indicate that it was in the as-received condition, although this is not clear.

Mason[1] measured a sample of annealed Ti-6Al-4V at 17.6 kHz at various strains (figure 6; see table 5 and note 2 above). (Note: for clarity some extraneous curves from Mason's original figure have been removed from figure 6.) Mason found that the internal friction (the inverse of the Q) was constant at 0.00005 (Q = 20000) (p. 1925) up to a strain of about 0.003 after which the it rapidly increased (i.e., the loss increased and the Q decreased). This limiting strain corresponds to a stress of about 320 MPa [46 kpsi]. Mason found that the increase in internal friction was not necessarily reversed upon subsequent annealing (p. 1926). (Wood[1] found similar behavior for annealed titanium (unknown grade) when tested at 20 kHz.)

|

|

|

|

In low amplitude tests Mason found that the internal friction was independent of frequency up to 104 kHz and decreased "only slightly" at high temperatures (figure 7; see table 5 and note 3 above).

|

|

|

Variability

In Mason's work above, the number of tested samples is not known so the variability is not known. However, Mason's figure 7 (p. 1931) shows that the internal friction for two well annealed samples differed by almost 2:1.

Wuchinich[3] reports a Q of ~5000 for two annealed samples. This is only 1/4 of the value reported by Mason[1].

Comparison to other materials

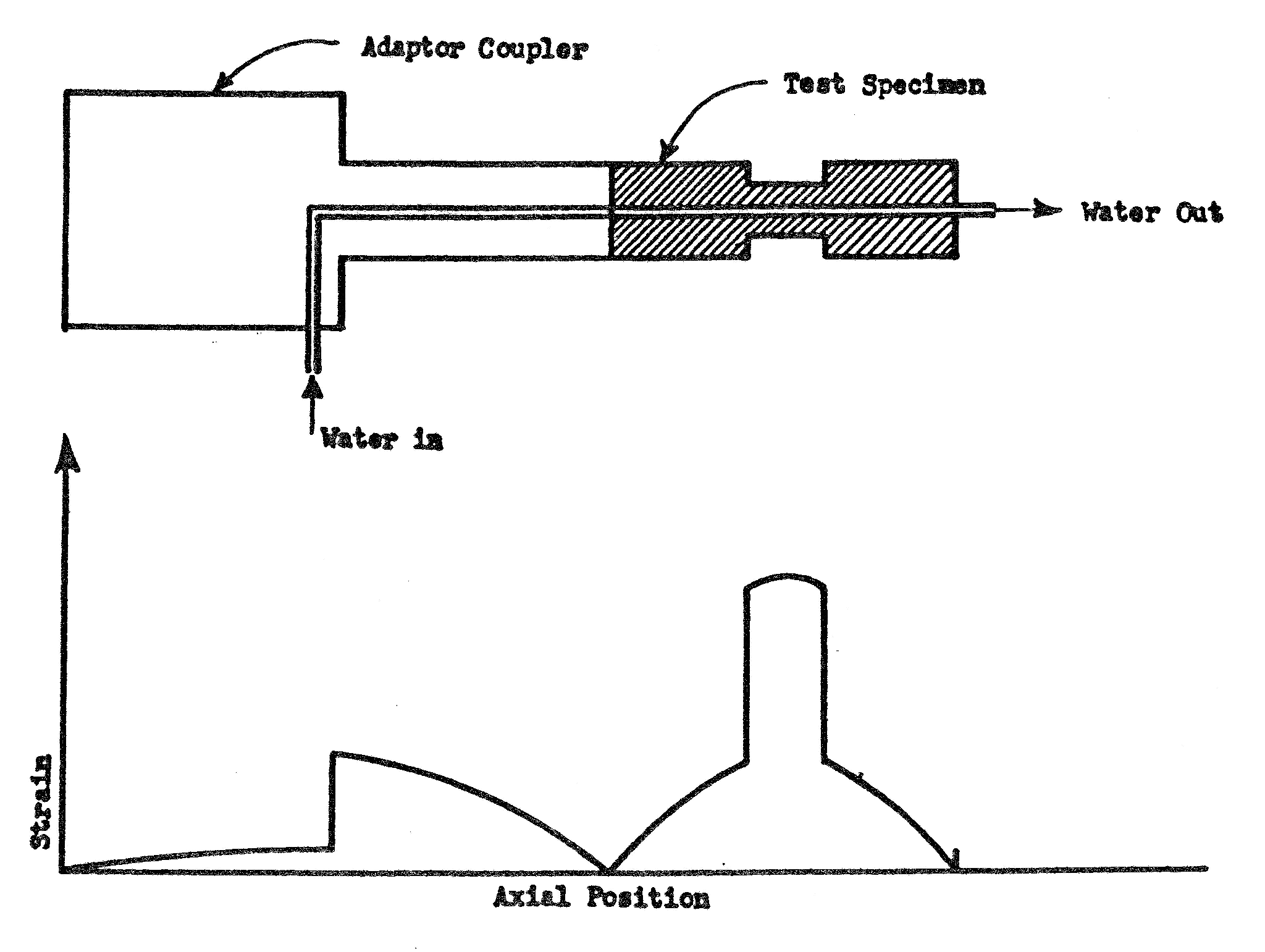

Aeroprojects conducted resonant tests on various metals to determine their acoustic losses (circa 1969). The tests measured the temperature rise of water that flowed through the center of a highly stressed 15 kHz horn (figure 8).

|

|

|

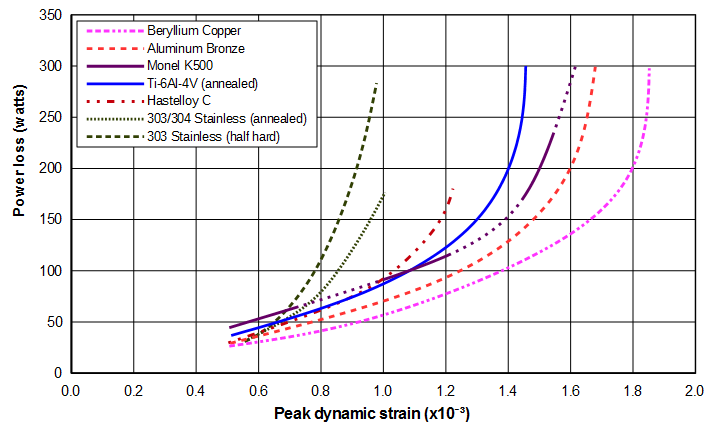

The results (reported by Maropis[0] to Culp[0]) are shown in figure 9. Note that the losses are only valid for the particular frequency and sample shape. However, comparisons among the various materials are still valid.

The Aeroprojects data indicate that the Ti-6Al-4V loss continually increases with increasing strain, with the accelerated loss at higher strains. Also, the Aeroprojects data shows that Ti-6Al-4V is superior to the tested steels. Although the Ti-6Al-4V's loss is higher than beryllium copper, aluminum bronze, and monel K500, it may have other advantages (e.g., less expensive, superior fatigue strength, better machinability, etc.).

Notes —

- See here for the original hand-drawn Aeroprojects graph with additional steels that have even higher losses.

- The Aeroproject results in figure 9 are for loss whereas Mason's results in figure 6 are for the Q; hence, these results can't be directly compared.

|

|

|

Fatigue

See a general discussion of fatigue. In addition, the following are specific to titanium.

The following factors should be considered when comparing real-world fatigue to laboratory S‑NL data and when interpreting S‑NL graphs.

Grain direction

Fatigue may be affected by direction of the grain relative to the principal stress. For example, see the graph of Boyer[1] (p. 431) below. (Original source: Polmear, I. J., Light Alloys, American Society for Metals, Metals Park, OH, 1981, p. 193) Note that, unlike Bowen above, the longitudinal direction has considerably longer life than the long transverse direction.

The effect of cross rolling on fatigue is not known. However, given the critical reliability requirements of the aero-engine compressor blades for which it is used, one would assume that the fatigue performance would be exceptional.

|

|

|

Etching

The grain direction in titanium can be checked (either before or after machining) with Kroll's Reagent (1% HF (hydrofluoric acid), 12% HNO3 (nitric acid), balance water) which is available commercially.

Frequency

In the absence of extenuating circumstances, ultrasonic fatigue tests often show reasonable agreement with conventional low-frequency S‑N fatigue tests (see figure 11 for an example) but this issue is not completely resolved. See Wells[1]. Also see Neppiras[1B] (p. 707) who states, "Measurements have confirmed that the fatigue limit is a function of the operating frequency [comparing ultrasonic results to low-frequency tests]." (Note, however, that this statement does not specifically refer to titanium.)

Forming process

The material may be formed by forging, extruding, rolling, cross-rolling, etc. Each of these can result in different fatigue properties.

Heat treatment

Titanium's heat treatment will affect the endurance limit. For example, matweb.com gives 510 MPa for generic annealed unnotched Ti–6Al–4V at 107 cycles versus 700 MPa for STA (solution treated and aged). However, see Appendix E for important notched results. (Important: the test conditions were not specified. Therefore, these endurance limits should only be used for comparison.)

Notch sensitivity

Some materials have good fatigue performance in the unnotched condition but their performance deteriorates relatively significantly in the notched condition. See Appendix E for the notch sensitivity of Ti–6Al–4V STA.

Residual stresses

Residual tensile stresses may reduce the fatigue life. On the other hand Donachie[1] (p. 177) notes, "One further observation about titanium alloys is that fatigue data reported in the literature often may be on material with favorable surface residual stress induced by turning, milling, etc. Fully stress-relieved or chem-milled surfaces probably have fatigue strengths below the reported alloy capabilities, because the latter have been biased upward by the favorable — that is compressive — stresses."

Note that some machining operations (e.g., harsh electro-discharge machining EDM (discussed elsewhere), harsh grinding) can induce high residual tensile stresses.

Processing

Fatigue may be affected by how the material is processed and the resulting microstructure. Figure 11 (Willertz[1], p. 341) shows this effect for fine grained α‑β, tested in pure water, where the lamellar microstructure performed significantly better than the equiaxed microstructure. The test samples were cylindrical so the material form is not sheet; however, other information is not available. (Note in this case the general agreement between the results at conventional and ultrasonic frequencies.)

|

|

|

Recommended maximum stress and strain

Considering both loss and fatigue, the maximum stress should generally be limited to 320 MPa [46 kpsi; ~0.0029 strain] — 350 MPa [50 kpsi; ~0.0032 strain].

- Loss. As discussed above, the loss can quickly increase for strains above 0.003 which corresponds to a stress of about 320 MPa (but depending on Young's modulus which can vary somewhat). Additional cooling (e.g., water for surgical instruments) may allow greater stress for slender resonators. However, additional surface cooling on relatively thick resonators (e.g., bar horns) may not be effective in removing the heat because titanium has poor thermal conductivity. In this case reduced stress may be necessary.

- Fatigue. Considering the many variables involved in fatigue, then for annealed Ti-6Al-4V whose principal vibration is parallel to the longitudinal grain direction, the literature and experience suggest that (as a rough rule of thumb) the maximum peak alternating stress should not exceed 350 MPa [50 kpsi; ~0.0032 strain] under normal conditions (reasonable surface finish, no residual stress, no corrosives, etc.), assuming that essentially infinite life is needed.

(Wuchinich[4] (p. 7) asserts, "The safe value of vibrational stress has been determined by experimentation to be one-third the value of the yield stress (the stress at which the metal begins to irreversibly deform)." This would give a maximum safe stress of approximately 300 MPa [43 kpsi; ~0.0027 strain].

Mathieson[1] (p. 58) gives a limiting value of 200 MPa [29 kpsi; ~0.0018 strain].

Bromfield[4] (p. 16) gives a limiting value of 390 MPa [57 kpsi; ~0.0035 strain].

The above assume proper machining — good surface finish with low residual stress.

Special circumstances may allow a somewhat higher stress or require a lower stress. For applications where failure may have severe consequences (e.g., surgical probes), lower stress limits may be appropriate.

Ti-6Al-4V — other conditions

In addition the annealed condition, Ti-6Al-4V is also avaliable as STA (solution treated and aged) and ELI (extra low interstitial).

Ti-6Al-4V STA (Solution Treated and Aged)

Solution treating and aging is a common method for increasing the strength of Ti-6Al-4V. (See TIMET[1], p. 10 for details.) The following table from matweb.com compares Ti-6Al-4V STA with annealed Ti-6Al-4V. (ELI material has also been included for completeness.) In most respects Ti-6Al-4V STA appears superior. For example, its unnotched (Kt = 1.0) fatigue strength is 37% higher. However, many ultrasonic resonators have significant "notches" (stress concentrations) due to radii from slots, flutes, etc. The matweb data show that for a stress concentration factor Kt = 3.3, Ti-6Al-4V STA actually has 33% lower fatigue strength than annealed. (Osgood[1] (pp. 440‑442) notes that titanium is very notch sensitive and that heat treatment intensifies this notch effect.)

|

||||||||||||||||||||||||||||

|

Contrary to the above, however, a graph from Boyer[1] (p. 430) below indicates that STA has superior fatigue in both the unnotched as well as the notched conditions. (Original source: Metals Handbook, 9th Edition, Volume 3, Properties and Selection: Stainless Steels, Tool Materials and Special‑Purpose Metals, American Society for Metals, Metals Park, OH, 1980, p. 389) Hence, the fatigue performance of STA compared to annealed is unclear. However, as discussed previously, the STA material has higher loss (lower Q) than the annealed material which may therefor limit its ability to operate at high stress.

|

|

|

Ti-6Al-4V ELI (Extra Low Interstitial)

Ti-6Al-4V ELI is a higher-purity ("extra-low interstitial") version of Ti-6Al-4V, with lower specified limits on iron and the interstitial elements carbon and principally oxygen. This yields superior toughness, especially at low temperatures.

There is some suggestion that this material may be superior for ultrasonic applications, either through a more consistent Young's modulus or better fatigue strength. Osgood[1] (figure 10.49, p. 422) lists the unnotched fatigue strength of Ti-6Al-4V ELI as 635 MPa [92 kpsi] at 107 cycles versus 515 MPa [75 kpsi] for Ti-6Al-4V, a 23% improvement. (Osgood does not specify the material's condition.) On the other hand, matweb.com gives 300 MPa [44 kpsi] for Ti-6Al-4V ELI versus 510 MPa [74 kpsi] for Ti-6Al-4V annealed material under the same conditions (a 41% decrease).

Ti-7Al-4Mo

Although most resonator manufacturers use Ti-6Al-4V, Branson Ultrasonics uses Ti-7Al-4Mo (7% aluminum, 4% molybdenum), typically from TIMET. Branson switched from Ti-6Al-4V to Ti-7Al-4Mo in the early 1970's.

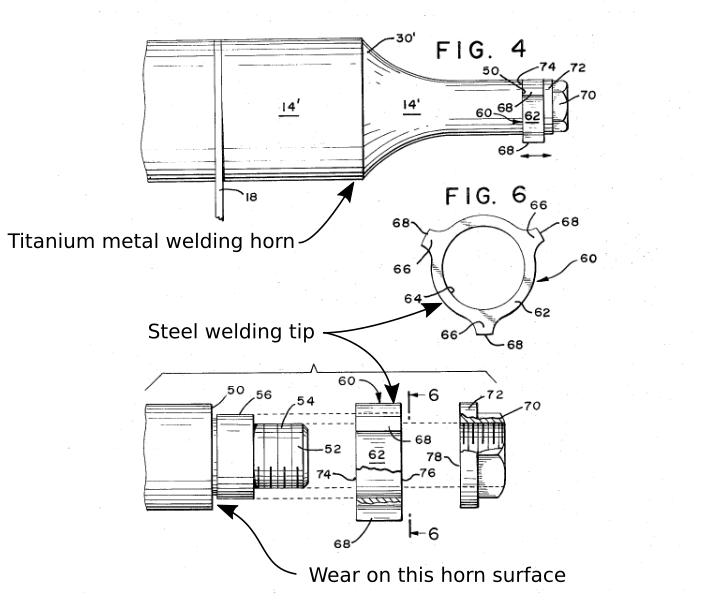

- During the development of Branson's ultrasonic metal welder, the ultrasonic welding stress on the welding lobe of the steel welding ring would eventually cause the adjacent horn interface to deteriorate (figure 13). Ti-7Al-4Mo seemed to give improved life.

- Ti-7Al-4Mo seemed to reduce the variability in tuned lengths (i.e., a more consistent Young's modulus).

|

|

|

The literature suggests that this material may have higher fatigue strength than Ti-6Al-4V. One source (reported by Culp[0]) found that titanium tips with cut threads were less likely to experience thread fatigue failures when they were made of Ti-7Al-4Mo instead of Ti-6Al-4V. (It is not known if these materials were annealed or STA.)

|

||||||||||||||||

|

Table 8 shows the proposed benefits of Ti-7Al-4Mo compared to Ti-6Al-4V (Branson's Technolog TL-18). (Note — the Technolog does not specify the condition of the Ti-7Al-4Mo. However, comparing the ultimate strengths and yield strengths in Table 7, Branson's material appears to be annealed rather than STA.)

|

||||||||||||||

|

Table discussion notes —

- For most resonators, as long as the resonator material is strong enough to prevent the threads in the stud hole from stripping then material strength is irrelevant. However, a stronger material would be beneficial for impact applications including, for instance, metal welding horns with replaceable tips.

- Ultrasonic resonators are not placed under sufficient tension or compression at any reasonable operating temperature so as to cause creep. Hence, creep is irrelevant.

- This is possible but no data are provided.

- The meaning is unclear unless this indicates that Ti-7Al-4Mo is more isotropic. Even so, the performance benefit is unclear. However, FEA results (modeled using isotropic material properties) would more closely match the actual resonator.

- The maximum allowable resonator stress is determined by the material's fatigue strength. Since fatigue generally occurs at notches (e.g., slot ends), the notched fatigue strength is the limiting factor.

For unnotched titanium the fatigue strength increases roughly linearly with the ultimate tensile strength (Osgood[1], p. 441). For example, Table 9 compares Ti-6Al-4V STA material (1170 GPa ultimate strength) to annealed Ti-6Al-4V (950 GPa ultimate strength). In the unnotched condition the STA material has 38% greater fatigue strength than the annealed material. However, when a notch is added to both materials with a 3.3 stress concentration factor, the STA material has 33% lower fatigue strength.

Now consider Ti-7Al-4Mo. It's ultimate tensile strength is 15% higher than Ti-6Al-4V (1040 MPa versus 900 MPa according to Branson's data) which would likely give higher unnotched fatigue strength. However, there is no guarantee that Ti-7Al-4Mo would have better notched fatigue strength; in fact, it could be worse. - Almost all resonators are tuned from the face where only the mass-density of the material affects the tuning. Given the small length of material that is removed from the face (typically less than 6 mm at 20 kHz), any significant variation in density (which would lead to a variation in tuning rate) in this distance is extremely unlikely.

|

|||||||||||||||

|

Table notes —

- STA = solution treated (i.e., quenched) and aged

- Fatigue strength values are at 107 cycles.

Density

The usual density of Ti-7Al-4Mo is 4484 kg/m³. Note that this is 1.3% higher than Ti-6Al-4V (4430 kg/m³).

Modulus and wave speed variation

Fabrication

Conventional machining

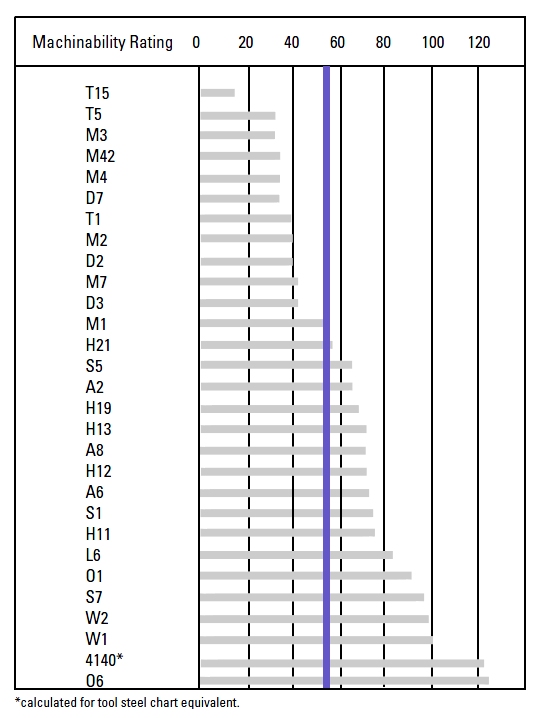

"Using the rating system based on AISI B1112 steel, the machinability of Ti-6Al-4V is rated at 22% of B1112. In general, low cutting speeds, heavy feed rates and copious amounts of cutting fluid are recommended. Also, because of the strong tendency of titanium to gall and smear, feeding should never be stopped while the tool and work are in moving contact. Non-chlorinated cutting fluids should be used to eliminate the possibility of chloride contamination. It should be noted that titanium chips are highly combustible and appropriate safety precautions are necessary." (Carpenter[1], p. 6)

Figure 14 shows the machinability of Ti-6Al-4V compared to various steels. The baseline for this data is steel W1 (a water hardening steel) at 100 (Bryson[1], p. 141). On the AISI B1112 scale, the machinability of W1 is 40% (Bryson[1], p. 141). (Note — The vertical blue line has been added. It represents the machinability of Ti-6Al-4V which is 22% on the AISI B1112 scale — i.e., 55% relative to W1.)

|

|

|

Notes —

- Carbide tools are recommended.

Tapping

Titanium can be difficult to tap because it conducts heat poorly. The retained heat may result in chipped cutting edges and reduced tap life. In addition, titanium tends to seize the tap which which can cause galling and tearing of the threads; this may, additionally, cause small diameter taps to break.

Work hardening ---

Special taps are available for titanium (figure 15).

|

|

|

|

The size of the pre-tapped hole will depend on such factors as the precision and condition of the drill and the type of equipment that is used to produce the hole (for example, CNC versus manually operated), etc. Hence, the limits of the drilled hole diameter should be specified rather than specifying a particular tap drill size.

Deep drilling

Deep, small diameter holes are often used for fluid passage in titanium medical probes. Rather than use conventional twist drills, these holes can be more easily and accurately machined using gun drills. Gun drills have a single longitudinal flute so they are stiffer than twist drills and they also have a central hole for cooling-lubricating fluid.

Electrical discharge machining (EDM)

Electrical discharge machining (EDM) has been tried for machining slots in block horns. However, the process is relatively slow and reduces the fatigue life. Details ... Also, many shops don't have in-house EDM equipment. Relying on outside vendors can potentially increase production turn-around time and impact quality control.

Recommendations

- For consistency of material properties, always order material from the same vendor and, preferably, from the same manufacturer.

- Always specify the grain direction on the resonator drawing.

- Whereas some rectangular horns are too large for bar stock, most rectangular horns can be machined from plate stock. Therefore, for maximum consistency plate stock should be used for rectangular horns where possible.

- Where the material dimensions permit, cylindrical horns should be machined from cylindrical stock rather than plate stock. This is because, although the material properties may vary radially, there should be little variation circumferentially so the amplitude variation at any given radius should be minimized. (If the horn were machined from plate stock with the stud axis in the thickness (short transverse) direction, then the amplitude at a given radius could vary due to differences in the plate's properties in the longitudinal and long-transverse material directions, both of which are transverse to the stud axis.)

- In order of preference, the grain direction (relative to the resonator's principal stress direction) should be specified as: 1) short transverse, 2) longitudinal, 3) long transverse. However, short transverse may not be available in sufficient size.

- For Ti-6Al-4V —

- Use annealed material because it has better fatigue and lower loss than STA material.

- Young's modulus

- For cylindrical stock Young's modulus may be taken from figure 2.

- For plate stock where the the grain direction parallel to the principal direction of vibration, 119.6 GPa is a reasonable first estimate for Young's modulus.

- Maximum stress.

Appendix A — Young's Modulus for Ø38.1 mm Ti-6Al-4V Rod

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Notes:

- The data are from Culp[0].

Appendix B — Young's Modulus for Ti-6Al-4V Plate

Longitudinal grain direction

A series of horns was machined with the grain direction parallel to the principal direction of vibration. Each horn was analyzed with FEA whereby Young's modulus was adjusted until the FEA frequency agreed with the actual horn's measured frequency. Young's modulus was thus determined as though the material were isotropic although the material is likely orthotropic.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Notes:

- The data are from Culp[0].

- All horns are bar horns.

- Horn dimensions are listed as "face width" x "face thickness" x "back thickness".

- All dimensions are rounded to the nearest mm.

- TIMET[2] is a titanium manufacturer. President Titanium[1] is a vendor that supplies titanium from various sources.

- The 35 kHz 83 mm x 5 mm x 23 mm horn has a modulus of 132.4 GPa. This appears to be an outlier. If this datum is excluded then the average modulus changes to 119.6 GPa (–0.5%).

- With this type of test, the attached transducer may have some effect on the frequency and, hence, on the determined modulus.

Appendix C — Titanium with Low Young's Modulus

The following titanium have a Young’s modulus that is appreciably lower than normal. This gives a lower wave speed and, therefore, a lower tuned length at a specified frequency.

Niinomi[1A] (p. 2) notes, "Developing the fatigue strength and simultaneously lowering Young’s modulus is somewhat difficult because they are opposite natures when the bonding force between atoms is considered." Many of the alloys contain niobium (Nb).

These titanium may be used for bone implants because their low moduli more nearly match that of bone.

The following list is not comprehensive.

Ti‑29Nb‑13Ta‑4.6Zr (TNTZ)

Niinomi[1A] reports a modulus of 60 GPa (55 GPa if severely cold worked). Under certain conditions the fatigue strength of this material is comparable to Ti-6Al-4V ELI (Niinomi[1A], figure 10, p. 3). This material may be used for biomedical applications. (Also see Niinomi[1B].)

Ti‑(5, 10, 15)Nb‑9Zr

Liu[1] investigated this material for 5%, 10%, and 15% concentrations of Nb (niobium). The stress-strain curves are shown in figure C1 along with the moduli. Note that the CR (cold rolled) material has the highest ultimate strength and is therefore also likely to have the highest fatigue strength. Liu suggested this material as a potential candidate for biomedical applications.

Also see Hosseini[1], pp. 79-80.

|

|

|

Ti-13Nb-13Zr

See here.Appendix D — Titanium for Biomedical Use

See Hosseini[1] for a general discussion of titanium alloys for biomedical use.

ASTM lists the following titanium alloys for implant use. Presumably they could also be used for ultrasonic surgical probes if their ultrasonic performances were acceptable.

- Ti unalloyed

- Ti‑6Al‑4V

- Ti‑6Al‑4V ELI

- Ti-6Al-7Nb

- Ti-13Nb-13Zr (see note 1)

- Ti-12Mo-6Zr-2Fe

- Ti-15Mo

- Ti-3Al-2.5V

Notes —

- "Compared to mill-annealed, standard grade Ti-6Al-4V, Ti-13Nb-13Zr was determined to have equivalent tensile strength and ductility, 30% lower elastic modulus (81±3 GPa [versus 113 GPa, p. 102]), equivalent 10 million cycle unnotched axial fatigue endurance limit (500 MPa), higher notched fatigue endurance limit at Kt = 3.0 (215 vs 170 MPa), 20% higher plane strain fracture toughness, 20% higher Charpy impact energy, 30-40% lower flexural and shear moduli, 40% lower corrosion rate in simulated body environments, and equivalent wear resistance. Cold working of Ti-13Nb-13Zr lowered its modulus to below 50 GPa while retaining the high strength." "Ti-13Nb-13Zr contains only titanium, niobium and zirconium, three of the five most biocompatible elements in the periodic table." (Mishra[1A], p. 107)

Note that the fatigue tests were conducted with a fatigue stress ratio R = 0.1 (p. 100). (R is the ratio of maximum to minimum alternating stress.) R = 0.1 indicates that the test specimens were under constant static tensile stress. In contrast, ultrasonic resonators only experience fully reversed inertial (dynamic) stresses during each cycle (i.e., R = -1). Therefore, Mishra's endurance limits should not be used in the design of ultrasonic resonators.

Liu[1] (figure 12, p. 565) (China) shows the following additional materials for implants —

- Ti-15Mo-5Zr-3Al (solution treated)

- Ti-12Mo-6Zr-2Fe

- Ti-35.3Nb-5.1Ta-7.1Zr

- Ti-29Nb-13Ta-4.6Zr (solution treated; see Niinomi[1A], Niinomi[1B])

- Ti-29Nb-13Ta-4.6Zr (aged; see Niinomi[1A], Niinomi[1B])

For implants there is some concern about the toxic effects of aluminum, vanadium, and nickel alloying agents (Hosseini[1], p. 78).

Appendix E — Other Titanium

Ti-6Al-4V sintered

In theory, sintering could be used to produce a resonator to near-net shape. Wuchinich[3] tested a sample of sintered Ti-6Al-4V at 20 kHz. The Q was ~15000 up to a stress of 360 MPa (strain = 0.0030) after which it dropped to 11500 at 410 MPa (strain = 0.0034) (Wuchinich figure 5). When a separate sample was annealed (730 °C for one hour, then air cooled) the Q dropped to ~5000. Fatigue performance is not known.

Ti-6Al-6V-2Sn

This material is used by Pratt & Whitney in its gas turbine engines (Donachie[1] , p. 15). Compared to Ti-6Al-4V the strength is higher but the fracture toughness and fatigue properties are lower (ASM[1] , p. 1811).

Wuchinich[3] tested this material at 20 kHz where it survived repeated 6 million cycle operation at 414 MPa. However, note that the specimen was water cooled so that a reasonable temperature could be maintained through its 3.2 mm diameter. Also —

- The sample was annealed for one hour at 700 °C followed by air cooling.

- A single sample was tested so additional tests may be warranted.

- Young's modulus was measured as 99.3 GPa. Thus, this material will tune somewhat shorter than Ti-6Al-4V whose modulus for this size is ~107 GPa.